EMAT(Electromagnetic acoustic transducer)

We have developed various EMATs!

|

Name |

Characteristics |

Applications |

|

Bulk-shear-wave EMAT |

Compact. Higher efficiency. Wide frequency range (0.1-100 MHz). |

Acoustoelastic stress measurements, bolt-axial stress measurements, grain-size measurements, monitoring fatigue and creep. |

|

Bulk-wave EMAT |

Simultaneous detection of the longitudinal wave and radially polarized shear waves. |

Stress measurement in a thin plate. |

|

Periodic-permanent-magnets (PPM) surface-SH-wave EMAT |

Surface shear waves with the frequency less than 2 MHz. |

Surface flaw detection, corrosion detection, formability evaluation |

|

Magnetostriction surface-SH-wave EMAT |

Higher frequency surface SH-waves. Lower efficiency. |

Surface flaw detection, corrosion detection, formability evaluation |

|

Axial-shear-wave EMAT |

Axial-shear resonances. Ability to evaluate the microstructure change along the radial direction of rods and pipes. |

Life assessment for fatigue and creep, induction hardness depth evaluation |

|

PPM SH-EMAT for pipeline |

It can run inside pipes measuring the outside corrosion defects. |

Fast detection of corrosion defects on pipelines. |

|

Magnetostriction EMAT for wires |

High efficiency, good at long-range detection of defects. |

long-range detection of flaw of wires |

|

Line-focusing EMAT |

The wavelength of the meander-line coil is smoothly changed for concentrating the SV wave at the focal line inside the material. |

Flaw detection |

|

High-temperature EMAT |

Free vibration resonance can be measured at high temperatures up to 1300 K. |

Measurement of the temperature dependence of the elastic constants and internal friction of small-scale materials. |

|

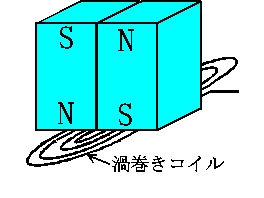

Bulk-Shear-Wave EMAT |

|

|

The bulk-shear-wave EMAT consists of a pair of permanent magnets and a spiral-elongated coil. Driving currents in the coil generate the electromagnet forces (Lorentz force and magnetostriction force) parallel to the surface to generate the shear waves propagating normal to the surface |

|

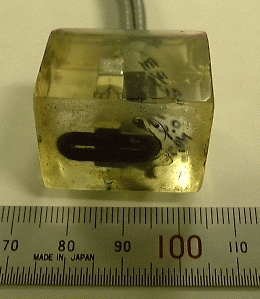

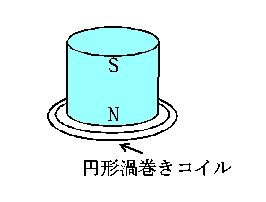

Bulk-Wave EMAT |

|

|

The bulk-wave EMAT, consisting of a single cylindrical magnet and a spiral coil, can simultaneously generate and detect the longitudinal wave and radially polarized shear waves propagating along the thickness direction. . |

|

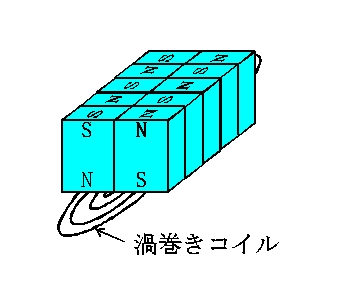

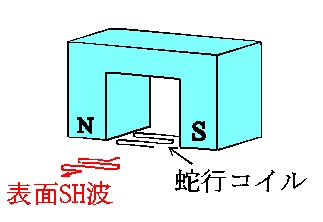

PPM Surface-SH-Wave EMAT |

|

|

PPM Surface-SH-Wave EMAT consists of many thin permanent magnets and a elongated spiral coil. It generates the surface SH wave with the same period of the permanent-magnet allay. The efficiency depends on the thickness of the magnets; usually, the magnet thinner than 1mm cannot produce high enough efficiency and the frequency of the surface wave is less than 1.5 MHz. |

|

Magnetostriction Surface-SH-Wave EMAT |

|

|

The meander-line coil and the tangential magnetic field can generate higher frequency surface-SH-waves via the magnetostriction effect. The frequency can be increased by decreasing the wavelength of the meander-line coil. The appropriate direction of the tangential magnetic field is about 45 degree from the straight lines of the meander-line coil for steels, and it is parallel to the straight lines for Ni. Thus, it highly depends on the magnetostriction curve of the material. |

|

Axial-Shear-Wave EMAT |

|

|

The axial-shear wave is the surface shear wave propagating in the circumferential direction on rods and pipes with the polarization direction along the axial direction. It causes resonance and the penetration depth depends on the resonant modes; higher modes more deeply penetrate. Therefore, using different resonance modes, we can evaluate the microstructure change along the radial direction. |

|

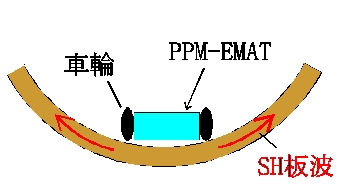

PPM EMAT for Pipe Inspection |

|

|

The PPM EMAT with wheels can run along the axial direction of pipelines, generating and receiveing the SH-plate wave along the circumference direction. The corrosion defects occurring outside are detected through the phase shift of the round-trip SH wave. This technique allows fast pipeline inspection. |

|

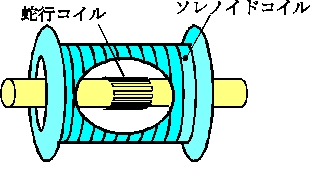

Longitudinal-Wave EMAT for Thin Wires |

|

|

The solenoidal coil and the axial magnetic field causes the longitudinal wave along the axial direction of thin wires with very high efficiency via the magnetostriction effect. Using the best magnetic field, the longitudinal wave can propagate as far as 100m, allowing the long-range inspection of defects. |

|

Line-Focusing EMAT |

|

Home:docs/Images/EMATs.08.Pic01.jpg |

|

The Line-focusing EMAT consists of a permanent magnet and the specially designed meander-line coil, whose distances between the straight –lines are changed so as to focus the SV wave at the focal point inside the material. It can detect the defects as long as 50micrometer located the back surface. |

|

High-Temperature EMAT |

|

|

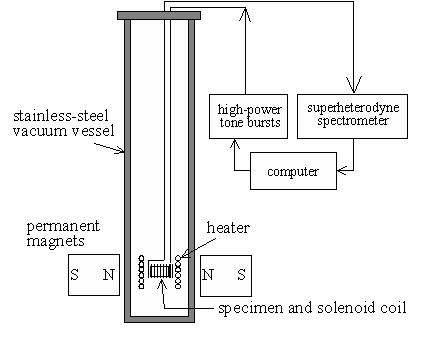

The specimen is inserted in a solenoid coil located within a stainless-steel cylindrical chamber. The solenoid coil is made with a Ni-alloy wire and its shape is held by a ceramic cement so as to operate at higher temperatures above 1300 K. A Cantal-line heater supplies the heat to the coil and specimen. Combination of rotary and diffusion pumps evacuates the air in the chamber from the bottom and keeps the pressure below 0.0001 Pa Torr for the specimen not to be oxidized. A pair of permanent magnets located outside the chamber provides the static-magnetic field to the specimen for the electromagnetic excitation and detection of free vibration via the Lorentz-force mechanism and the magnetostriction-force mechanism. The permanent-magnet assembly is mounted on casters, which facilitated the rotation of field direction about the cylinder axis and selection of the detectable vibration modes. |